Sébastien LEVENEUR

Welcome!

The research group is located at INSA Rouen Normandie. A part of the research is also done at ÅBO AKADEMI UNIVERSITY in Finland.

Our aim is to develop safe and intensified processes for the valorization of biomass.

In 2025, Yudong MENG successfully defended his doctoral thesis on structure-reactivity applied to the epoxidation of vegetable oils, thanks to the jury.

In 2022, our work was recognized by I&EC Research as one of the 2022 Class of Influential Researchers (2022 Class of Influential Researchers – Europe, Middle East, and Africa (acs.org))

Honored to share that one of our article became one of the most read in the Canadian Journal of Chemical Engineering.

Contact : sebastien.leveneur@insa-rouen.fr

Postdoctoral Research Associate

PhD Students

- Erny Encarnacion Munoz "Production of the renewable monomer" https://theses.fr/s392568

- Viktória Flóra Csendes “Development of safe, intensified and sustainable pRocEss for the vAlorization of lignocellulosic bioMass (DREAM)” https://theses.fr/s392611

- Daniel Edumujeze "Waste food vAlorization: Kinetics and thErmodynamics assessment to optimize biofUel

Production (WAKEUP)" https://theses.fr/s393049 - Shiyu ZHU “Security and Intensification of Biofuel Production from Lignocellulosic Biomass” https://theses.fr/s406979

Research engineer

- Jose Emilio DELGADO LIRIANO

Master's thesis

Bachelor's thesis

Our aim is to understand the reactivity of complex chemical systems: develop robust and reliable kinetic models in different thermal modes. We are using different calorimeters (RC1, C80, ARSST, etc), process intensification systems (micro-reactor, microwave irradiation) and statistical methods (Bayesian inferences, cross-validation, etc).

We have developed original approaches based on structure-reactivity and non-isothermal mode to develop robust and reliable kinetic models.

The following research activities are investigated:

• Risk assessment for the valorization of biomass processes

• Kinetic modeling of complex reaction system

• Microwave irradiation for the valorization of vegetable oil

• Microreactor for the valorization of 2nd generation biomass

• Structure-reactivity

In 2004, I got two master's theses: Chemical Engineering & Fine Chemistry (INSA Rouen) and Risk management of chemical hazards (University of Rouen). In 2005, I worked for nine months at Åbo Akademi University (Finland) on an industrial project (Kemira company). After this project, I started my doctoral thesis in joint degree between Åbo Akademi University and INSA Rouen on “Catalytic synthesis and decomposition of peroxycarboxylic acids” under the supervision of Prof. Tapio Salmi. In 2009, I got my Ph.D. degree with honors from both institutes and the European label. From 2009 to 2010, I continued as a junior researcher at Åbo Akademi University and focused my research on kinetic modeling on the continuous reactor.

I was appointed Assistant Professor at INSA Rouen in 2010 in the department “Risk management.” In 2015, I defended my Habillitation (University of Rouen) and became Associate-Professor. In 2015, I was also appointed Docent in chemical process technology, especially new concepts chemical in reaction engineering, modelling of chemical reactors and safety aspects at Åbo Akademi University. This position was renewed for life in 2020.

My research activities focus on developing kinetic models for complex chemical systems, the use of process intensification (microwave & microreactor) and risk analysis. These activities are devoted to biomass valorization.

POPULAR SCIENCE ARTICLES

I. “Valorisation de la biomasse : comment éviter les accidents industriels ?”, published in The Conversation in 2023 by S Leveneur and V Casson Moreno, https://theconversation.com/valorisation-de-la-biomasse-comment-eviter-les-accidents-industriels-215843

English version at :

BOOKS

I. Book “Process Synthesis and Process Intensification: Methodological Approaches”, de Gruyter, 2017, Coordinator: Ben-Guang Rong.

Book chapter: “Aspects on reaction intensification by microwave and ultrasound techniques in some chemical multiphase systems”, Contributors: T. Salmi, A.F. Aguilera, P. Tolvanen and S. Leveneur

PUBLICATIONS

2025

120. Xinglin Wen, Yonglu Yang, Yong Pan, Jitao Hu, Xiaoyue Wan, Yanhui Yang, Sébastien Leveneur, Juncheng Jiang, Safe andDirect Conversion of 2,4-Dinitrotoluene into 1-Methyl-2,4-Cyclohexane-Diamine: A One-Pot Hydrogenation Reaction Route Catalyzed by Lithium-Modified γ-Al2O3-Supported Ruthenium Nanoclusters, Fuel, accepted.

119. Viktória Flóra Csendes, Shakila Perera, Christine Devouge-Boyer, Mélanie Mignot, Karine Thomas, Sébastien Leveneur, Enhanced Butyl Levulinate Synthesis from Cellulose under High-Gravity Conditions: Catalyst and Solvent Optimization, Renewable Energy, Volume 250, September 2025, 123298, https://doi.org/10.1016/j.renene.2025.123298

HAL https://hal.science/view/index/docid/5060480

118. Iman Bahrabadi Jovein, Sindi Baco, Gabriele Sadowski, Ferruccio Doghieri, Ferruccio Doghieri, Marco Giacinti Baschetti, Gangqiang Yu, Sébastien Leveneur, Julien Legros, Christoph Held, Comprehensive Compilation on Esterification Reactions and Predicting Reaction Kinetics and Equilibrium Using PC-SAFT, ACS Engineering Au, https://doi.org/10.1021/acsengineeringau.5c00002

HAL https://hal.science/hal-05018931

117. Yong Pan, Chaoqin Ren, Jingshu Jin, Yanjun Wang, Sébastien Leveneur, Juncheng Jiang, Acid-base synergetic effect and thermal risk assessment on homogeneous catalytic production of γ-valerolactone with formic acid, Journal of loss prevention in the process industries, Volume 96, August 2025, 105636, https://doi.org/10.1016/j.jlp.2025.105636

HAL https://hal.science/hal-04989959

116. Marcel, Klinksiek; Sindi, Baco; Sebastien, Leveneur; Julien, Legros; Christoph, Held, Predicting proton activity and acid dissociation equilibria in mixed-solvent systems, and their impact on esterification kinetics of levulinic acid, Industrial And Engineering Chemistry Research, 64, 11, 6188–6202, https://doi.org/10.1021/acs.iecr.5c00115

HAL https://hal.science/hal-04986610

115. M-E. Clavel, W. Vasquez, A. Vandel, B. Quevreux, S. Leveneur, F. Collin-Bastiani, G. Cabot, B. Renou, Design and application of low pressure and low temperature facility to study aeronautical flame during pull-away, Review of Scientific Instruments, 96, 035106 (2025), https://doi.org/10.1063/5.0244870

HAL https://hal.science/hal-05060511

114. Daniele Di Menno Di Bucchianico, Giordano Emrys Scarponi, Jean-Christophe Buvat, Sébastien Leveneur, Valeria Casson-Moreno, Sustainable design of biomass valorization processes for the production of gamma-valerolactone integrating wind energy and green hydrogen, Journal of Cleaner Production, Volume 491, 1 February 2025, 144829. https://doi.org/10.1016/j.jclepro.2025.144829

Open access: https://hal.science/hal-04905885

113. Lujie Shi, Younes Aoues, Valeria Casson-Moreno, Yankai Wang, Sébastien Leveneur Surrogate modeling-based uncertainties analysis for the determination of safe and optimal operating conditions in batch reactor, Computers & Chemical Engineering, Volume 192, January 2025, 108909, https://doi.org/10.1016/j.compchemeng.2024.108909

Open access: https://doi.org/10.1016/j.compchemeng.2024.108909 & https://hal.science/hal-04762703

112. Daniel Edumujeze; Marie-Christine Fournier-Salaun; Sebastien Leveneur, Production of furfural: from kinetics to process assessment, Fuel, Volume 381, Part B, 1 February 2025, 133423. https://doi.org/10.1016/j.fuel.2024.133423

Open access: https://hal.science/hal-04744561 or https://doi.org/10.1016/j.fuel.2024.133423

2024

111. Yudong Meng, Elano Nery Ferreira, Nágila Maria Pontes Silva Ricardo, Nasreddine Kebir, Sebastien Leveneur, Epoxidation showdown: unveiling the kinetics of vegetable oils vs. their methyl ester counterparts, Industrial & Engineering Chemistry Research, 2024, 63, 44, 18849–18860 doi: https://doi.org/10.1021/acs.iecr.4c02712 .

Open access: https://hal.science/hal-04752397

110. Zhongchen Ma, Yong Pan, Jiajia Jiang, Lei Ni, Sébastien Leveneur, Juncheng Jiang, Determining the Safe Operating Conditions for Gas-Liquid Heterogeneous Reactions in an Isochoric Semi-Batch Reactor, Chemical Engineering Journal, https://doi.org/10.1016/j.cej.2024.155481

Open access: https://hal.science/hal-04689720

109. Jianchao Wang, Yong Pan, Yanjun Wang, Lei Ni, Sébastien Leveneur, Process optimization and scale-up of toluene nitration in a microchannel reactor using HNO3-AC2O as nitrating agent, Chemical Engineering and Processing- Process Intensification, Volume 204, October 2024, 109934, https://doi.org/10.1016/j.cep.2024.109934

Open access: https://hal.science/hal-04671640

108. Daniele Di Menno Di Bucchianico, Giordano Emrys Scarponi, Jean-Christophe Buvat, Sébastien Leveneur, Valeria Casson-Moreno, From biomass-derived fructose to γ-valerolactone: process design and technoeconomic assessment, Bioresource Technology, 401 (2024) 130753, https://doi.org/10.1016/j.biortech.2024.130753

Open access: https://hal.science/hal-04563031

107. Sébastien Leveneur, Pasi Tolvanen, Vincenzo Russo, Editorial Catalytic Epoxidation Reaction, Catalysts 2024, 14(5), 285; https://doi.org/10.3390/catal14050285

Open access: https://doi.org/10.3390/catal14050285 & https://hal.science/hal-04557037

106. Lujie Shi, Younes Aoues, Sébastien Leveneur, Impact of aleatory and epistemic uncertainties on thermal risk and production assessment: application to the hydrogenation of levulinic acid and butyl levulinate, Journal of Loss Prevention in the Process industries, 89 (2024) 105317, https://doi.org/10.1016/j.jlp.2024.105317

Open access: https://doi.org/10.1016/j.jlp.2024.105317 & https://hal.science/hal-04548473

105. Erny Encarnacion Munoz, Daniele Di Menno Di Bucchianico, Christine Devouge-Boyer, Julien Legros, Christoph Held, Jean-Christophe Buvat, Valeria Casson Moreno, Sébastien Leveneur, Combination of linear solvation energy and linear free-energy relationships to aid the prediction of reaction kinetics: application to the solvolysis of 5-HMF by alcohol to levulinate, Chemical Engineering Research and Design, Volume 205, May 2024, Pages 312-323, https://doi.org/10.1016/j.cherd.2024.03.040

Open access: https://hal.science/hal-04527410 & https://doi.org/10.1016/j.cherd.2024.03.040

104. Xiao-Shuang Cai, Hui-Xian Guo, Xiao-Juan Zhao, Hua-Min Liu, Yu-Xiang Ma, Sébastien Leveneur, Xue-De Wang, Catalytic Cycloaddition of CO2 to Epoxidized Methyl Oleate Over a HBimCl-NbCl5/HCMC: Physicochemical, Mass transfer and Kinetic Investigation, Chemical Engineering Science, https://doi.org/10.1016/j.ces.2024.119964

Open access: https://hal.science/hal-04489401v1

103. Sébastien Leveneur, Combining isothermal and adiabatic mode experiments for kinetic constants estimation: application to the hydrogenation of 5-(hydroxymethyl)furfural (5-HMF), Industrial & Engineering Chemistry Research, https://doi.org/10.1021/acs.iecr.3c04346

Open access: https://hal.science/hal-04486618

102. Juliette Vievard, Abdellah Alem, Anne Pantet, Nasre-Dine Ahfir, Sébastien Leveneur Christine Devouge-Boyer, Daïch Elias, Melanie Mignot, Competitive and non-competitive adsorption of seven heavy metals on flax fibers, Emergent Materials, https://doi.org/10.1007/s42247-024-00648-7

Open access: https://hal.science/hal-04481173v1

101. Sindi Baco, Marcel Klinksiek, Mélanie Mignot, Christoph Held, Julien Legros, and Sébastien Leveneur, Temperature effect on the steric and polar Taft substituent parameter values, Reaction Chemistry & Engineering, 2024, 9, 833–841,, https://doi.org/10.1039/D3RE00500C

Open access: https://hal.science/hal-04373628

100. Tapio Salmi, Wander Y. Perez-Sena, Fabrizio Ciccarelli, Kari Eränen, Ananias Medina, Martino Di Serio, Johan Wärnå, Sébastien Leveneur, Vincenzo Russo, Kinetics and reactor modelling of a complex three-phase system: carbonation of epoxides on grafted catalysts, Chemical Engineering Science 285 (2024) 119578, https://doi.org/10.1016/j.ces.2023.119578

Open access: https://normandie-univ.hal.science/hal-04337624

2023

99. Yudong Meng, Nasreddine Kebir, Sebastien Leveneur, Reactivity and Structure: Epoxidation of Cottonseed Oil and the Corresponding Fatty Acid Methyl Ester, Biomass Conversion and Biorefinery, https://doi.org/10.1007/s13399-023-04985-1

Open access: https://hal.science/hal-04245671

98. Wenel Naudy Vásquez Salcedo, Mélanie Mignot, Bruno Renou, Sébastien Leveneur, Assessment of kinetic models for the production of γ-valerolactone developed in isothermal, adiabatic and isoperibolic conditions, Fuel, Volume 350, 15 October 2023, 128792; https://doi.org/10.1016/j.fuel.2023.128792

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-04115376

97. Viktoria Flora Csendes, Attila Egedy, Sebastien Leveneur, Alex Kummer, Application of multi-software modelling in process system engineering: A review and a γ-valerolactone production case study, Processes, 2023, 11(5), 1503; https://doi.org/10.3390/pr11051503

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-04099597

96. S Leveneur, Kinetic modeling: Regression and validation stages, a compulsory tandem for kinetic model assessment, The Canadian Journal of Chemical Engineering, 2023;101:7078–7101, doi: 10.1002/cjce.24956

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-04103190

95. Daniele Di Menno Di Bucchianico, Mélanie Mignot, Jean-Christophe Buvat, Valeria Casson Moreno, Sébastien Leveneur, Production of butyl levulinate from the solvolysis of high-gravity fructose over heterogeneous catalyst: in-depth kinetic modeling, Chemical Engineering Journal, Volume 465, 1 June 2023, 142914, https://doi.org/10.1016/j.cej.2023.142914

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-04066613

94. Yudong Meng, Nasreddine Kebir, Xiaoshuang Cai and Sebastien Leveneur, In-depth kinetic modeling and chemical analysis for the epox-idation of vegetable oils in a liquid-liquid-solid system, Catalysts 2023, 13, 274. https://doi.org/10.3390/catal13020274

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-03957361

93. Jose Delgado, Wenel Naudy Vasquez Salcedo, Christine Devouge-Boyer, Jean-Pierre Hebert, Julien Legros, Bruno Renou, Christoph Held, Henrik Grenman, Sébastien Leveneur, Reaction enthalpies for the hydrogenation of alkyl levulinates and levulinic acid on Ru/C– influence of experimental conditions and alkyl chain length, Process Safety and Environmental Protection, 171, March 2023, Pages 289-298, https://doi.org/10.1016/j.psep.2023.01.025

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-03935524

92. Wenel Naudy Vásquez Salcedo, Bruno Renou, Sébastien Leveneur, Thermal Stability for the Continuous Production of γ-valerolactone from the hydrogenation of n-butyl levulinate in a CSTR, Processes, 2023, 11(1), 237, https://doi.org/10.3390/pr11010237

Open access: https://doi.org/10.3390/pr11010237

91. Alexandre Cordier, Marcel Klinksiek, Christoph Held, Julien Legros, Sébastien Leveneur, Biocatalyst and continuous microfluidic reactor for an intensified production of n-butyl levulinate: kinetic model assessment, Chemical Engineering Journal, Volume 451, Part 1, 1 January 2023, 138541, https://doi.org/10.1016/j.cej.2022.138541

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-03748632

2022

90. Katia Pérez, Sébastien Leveneur, Fabrice Burel, Julien Legros, Daniela Vuluga, Synthesis and Functionalization of Polymyrcene in a Flow Microreactor System, Reaction Chemistry & Engineering, https://doi.org/10.1039/D2RE00288D

89. Marcel Klinksiek, Sindi Baco, Sébastien Leveneur, Julien Legros, Christoph Held, Activity-based models to predict kinetics of levulinic acid esterification, ChemPhysChem, https://doi.org/10.1002/cphc.202200729

Open access: https://hal.science/hal-03825917

88. Suttiya Chiewudomrat, Sawitree Saengkaew, Gerard Grehan, Sébastien Leveneur, Lionel Estel, Evaluation of refractive index gradients in droplets by rainbow technique: application to CO2 capture by monoethanolamine aqueous spray, Experiments in Fluids (2022) 63:153, https://doi.org/10.1007/s00348-022-03495-6

87. Qiong Yu, Xiao-shuang Cai, Sébastien Leveneur, Xue-de Wang, Hua-min Liu, Chen-xia Zhang and Yu-xiang Ma, Kinetic modeling of the sesamin conversion into asarinin in the presence of citric acid loading on Hβ, Frontiers in Nutrition, https://doi.org/10.3389/fnut.2022.983843

Open access: https://www.frontiersin.org/articles/10.3389/fnut.2022.983843/full

86. Sindi Baco; Marcel Klinksiek; Rashid Ismail Bedawi Zakaria; Elizabeth Antonia García Hernandez; Melanie Mignot; Julien Legros; Christoph Held; Valeria Casson Morena; Sebastien Leveneur, Solvent effect investigation on the acid-catalyzed esterification of levulinic acid by ethanol aided by a Linear Solvation Energy Relationship, Chemical Engineering Science, Volume 260, 12 October 2022, 117928, DOI https://doi.org/10.1016/j.ces.2022.117928

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-03735962

85. Daniele Di Menno Di Bucchianico, Antonella Cipolla, Jean-Christophe Buvat, Mélanie Mignot, Valeria Casson Moreno, Sébastien Leveneur, Kinetic Study and Model Assessment for n-Butyl Levulinate Production from Alcoholysis of 5-(Hydroxymethyl)furfural over Amberlite IR-120, Industrial & Engineering Chemistry Research, 2022, 61, 30, 10818–10836, https://doi.org/10.1021/acs.iecr.2c01640

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-03731262

84. Elizabeth Antonia Garcia-Hernandez, Moulay Elhassane Elmoukrie, Sébastien Leveneur, Bouchaib Gourich, Lamiae Vernieres-Hassimi, Global sensitivity analysis to identify influential model input on thermal risk parameters: to cottonseed oil epoxidation, Journal of loss prevention in the process industries, Volume 77, July 2022, 104795, DOI https://doi.org/10.1016/j.jlp.2022.104795.

83. Nicolas Dietrich, Gaëlle Lebrun, Kalyani Kentheswaran, Mathias Monnot, Patrick Loulergue, Carine Franklin, Florence Teddé-Zambelli, Chafiaa Djouadi, Sébastien Leveneur, Mallorie Tourbin, Yolaine Bessière, Carole Coufort-Saudejaud, Annabelle Couvert, Eric Schaer, Rebalancing the historical female under-representation in education,

Journal of Chemical Education, 2022, 99, 6, 2298–2309, https://doi.org/10.1021/acs.jchemed.1c01218

Open access https://hal.archives-ouvertes.fr/hal-03666841v1

82. Daniele Di Menno Di Bucchianico, Jean-Christophe Buvat, Mélanie Mignot, Valeria Casson Moreno and Sébastien Leveneur, Role of solvent the production of butyl levulinate from fructose, Fuel, Volume 318, 15 June 2022, 123703, https://doi.org/10.1016/j.fuel.2022.123703.

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-03598350

81. Tapio Salmi, Vincenzo Russo, Adriana Aguilera, Pasi Tolvanen, Johan Wärnå, Martino Di Serio, Riccardo Tesser, Tommaso Cogliano, Sebastien Leveneur, Kari Eränen, A new perspective on vegetable oil epoxidation modeling: reaction and mass transfer in a liquid-liquid-solid system, AICHE Journal, Volume 68, Issue5, May 2022, e17626 doi: https://doi.org/10.1002/aic.17626 .

Open acces https://doi.org/10.22541/au.162603786.65718427/v1

80. Wander Perez-Sena, Kari Eränen, Narendra Kumar, Lionel Estel, Sébastien Leveneur, Tapio Salmi, New insights into the carbonation of epoxidized methyl oleate using single-component heterogeneous catalysts, Journal of CO2 Utilization, Volume 57, March 2022, 101879,

Open access https://doi.org/10.1016/j.jcou.2021.101879.

79. Daniele Di Menno Di Bucchianico, Yanjun Wang, Jean-Christophe Buvat, Yong Pan, Valeria Casson Moreno, Sébastien Leveneur, Production of levulinic acid and alkyl levulinates: A process insight, Green Chemistry, 2022, 24, 614–646. https://doi.org/10.1039/D1GC02457D

Open access https://hal.archives-ouvertes.fr/hal-03498103

78. Tapio Salmi, Pasi Tolvanen, Kari Eränen, Johan Wärnå, Sebastien Leveneur, Heikki Haario, Determination of kinetic constants by using transient temperature data from continuous stirred tank reactors, Chemical Engineering Science, Volume 248, Part B, 2 February 2022, 117164,

Open access https://doi.org/10.1016/j.ces.2021.117164

77. Jose Delgado, Wenel Naudy Vasquez Salcedo, Giulia Bronzetti, Valeria Casson Moreno, Mélanie Mignot, Julien Legros, Christoph Held, Henrik Grénman, Sébastien Leveneur, Kinetic model assessment for the synthesis of γ-valerolactone from n-butyl levulinate and levulinic acid hydrogenation over the synergy effect of dual catalysts Ru/C and Amberlite IR-120, Chemical Engineering Journal, Volume 430, Part 3, 15 February 2022, 133053, https://doi.org/10.1016/j.cej.2021.133053.

Open access https://hal.archives-ouvertes.fr/hal-03498093

76. Xiaojia Lu, Paula Junghans, Johan Wärnå, Gerd Hilpmann, Rüdiger Lange, Heather Trajano, Kari Eränen, Lionel Estel, Sebastien Leveneur, Henrik Grenman, Hydrolysis of semi-industrial aqueous extracted xylan from birch (betula pendula) employing commercial catalysts – kinetics and modelling, Journal of Chemical Technology & Biotechnology, Volume 97, 2022, Issue1, Pages 130-139

Open access https://doi.org/10.1002/jctb.6918.

2021

75. Xiaojia Lu, Lucas Lagerquist, Kari Eränen, Jarl Hemming, Patrik Eklund, Lionel Estel, Sebastien Leveneur, Henrik Grenman, Reductive catalytic depolymerization of semi-industrial wood-based lignin, Industrial & Engineering Chemistry Research, 2021, 60, 16827−16838

Open access https://doi.org/10.1021/acs.iecr.1c03154

74. Xiaojia Lu, Paula Junghans, Stephanie Weckesser, Johan Wärnå, Gerd Hilpmann, Rüdiger Lange, Heather Trajano, Kari Eränen, Lionel Estel, Sebastien Leveneur, Henrik Grénman, One flow through hydrolysis and hydrogenation of semi-industrial xylan from birch (betula pendula) in a continuous reactor– kinetics and modelling, Chemical Engineering and Processing - Process Intensification, 169 (2021) 108614

Open access https://doi.org/10.1016/j.cep.2021.108614

73. Daniele Di Menno Di Bucchianico, Wander Y. Perez-Sena, Valeria Casson Moreno, Tapio Salmi and Sébastien Leveneur, Model discrimination for hydrogen peroxide consumption to-wards γ-alumina in homogeneous liquid and heterogeneous liquid-liquid systems, Processes, 2021, 9, 1476.

Open access https://doi.org/10.3390/pr9081476

72. S. Capecci, Y. Wang, J. Delgado, V. Casson Moreno, M. Mignot, H. Grenman, D. Yu. Murzin, S. Leveneur, Bayesian statistics to elucidate the kinetics of γ-valerolactone from n-butyl levulinate hydrogenation over Ru/C, Industrial & Engineering Chemistry Research, 2021, 60, 31, 11725–11736. https://doi.org/10.1021/acs.iecr.1c02107

Open access https://hal.archives-ouvertes.fr/hal-03498097

71. Xiaoshuang Cai, Pasi Tolvanen, Pasi Virtanen, Kari Eränen, Jani Rahkila, Sébastien Leveneur, Tapio Salmi, Kinetic study of the carbonation of epoxidized fatty acid methyl ester catalyzed over heterogeneous catalyst HBimCl-NbCl5/HCMC, International Journal of Chemical Kinetics, 2021, 53, 1203-1219, 10.1002/kin.21526.

Open access https://hal.archives-ouvertes.fr/hal-03498076

70. Yudong Meng, Francesco Taddeo, Adriana Freites, Xiaoshuang Cai, Vincenzo Russo, Pasi Tolvanen, Sébastien Leveneur, The Lord of the Chemical Rings: catalytic synthesis of im-portant industrial epoxide compounds, Catalysts 2021, 11, 765.

Open access https://doi.org/10.3390/catal11070765

69. D. Lefebvre, S. Leveneur, Editorial Special Issue on “Thermal Safety of Chemical Processes”, Processes, 2021, 9(6), 1054.

Open access https://doi.org/10.3390/pr9061054

68. N. Zora, T. Rigaux, J.-C. Buvat, D. Lefebvre, S. Leveneur, Influence assessment of inlet parameters on thermal risk and productivity: application to the epoxidation of vegetable oils, Journal of Loss Prevention in the Process Industries, Volume 72, September 2021, 104551. https://doi.org/10.1016/j.jlp.2021.104551

Open access https://hal.archives-ouvertes.fr/hal-03498083

67. M. Errico, R. Stateva, S. Leveneur, Novel intensified alternatives for purification of levulinic acid, Processes, 9(3) (2021) 490.

Open access https://doi.org/10.3390/pr9030490

66. Luping Zhou, Shuqi Dai, Shuai Xu,Yuqi She, Yuliang Li, Sebastien Leveneur, Yanlin Qin, Piezoelectric effect synergistically enhances the performance of Ti32-oxo-cluster/BaTiO3/CuS p-n heterojunction photocatalytic degradation of pollutants, Applied Catalysis B: Environmental, 291 (2021) 120019, https://doi.org/10.1016/j.apcatb.2021.120019

65. S. Capecci, Y. Wang, V. Casson Moreno, C. Held, S. Leveneur, Solvent effect on the kinetics of the hydrogenation of n-butyl levulinate to γ-valerolactone, Chemical Engineering Science, 231 (2021) 116315 https://doi.org/10.1016/j.ces.2020.116315

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-03144830

64. W. Y. Pérez-Sena, J. Wärnå, K. Eränen, P. Tolvanen, L. Estel, S. Leveneur, T. Salmi, Use of semibatch reactor technology for the investigation of reaction mechanism and kinetics: heterogeneously catalyzed epoxidation of fatty acid esters, Chemical Engineering Science, 230 (2021) 116206

Open access https://doi.org/10.1016/j.ces.2020.116206

2020

63. A. Egedy, A. Kummer, S. Leveneur, T. Varga, T. Chován, CFD modelling of spatial inhomogeneities in a vegetable oil carbonation reactor, Processes, 8 (2020) 1356;

Open access https://doi.org/10.3390/pr8111356

62. Xiaojia Lu, Yanjun Wang, Lionel Estel, Narendra Kumar, Henrik Grénman, Sébastien Leveneur, Evolution of specific heat capacity with temperature for typical supports used for heterogeneous catalysts, Processes, 8(8) (2020) 911.

Open access https://doi.org/10.3390/pr8080911

61. Yanjun Wang, Igor Plazl, Lamiae Vernières-Hassimi, Sébastien Leveneur, From calorimetry to thermal risk assessment: γ-valerolactone production from the hydrogenation of alkyl levulinates, Process Safety and Environmental Protection, 144 (2020) 32-41 https://doi.org/10.1016/j.psep.2020.07.017

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-03144825

60. Andrés Felipe Guzmán Agudelo, Wander Y. Pérez-Sena, Nasreddine Kebir, Tapio Salmi, Luis Alberto Ríos, Sébastien Leveneur, Influence of steric effects on the kinetics of cyclic-carbonate vegetable oils aminolysis, Chemical Engineering Science, 228 (2020) 115954 https://doi.org/10.1016/j.ces.2020.115954

Open access https://hal.archives-ouvertes.fr/hal-03515972

59. Vincenzo Russo, Riccardo Tesser, Carmelina Rossano, Tommaso Cogliano, Rosa Vitiello, Sébastien Leveneur, Martino Di Serio, Kinetic study of Amberlite IR120 catalyzed acid esterification of levulinic acid with ethanol: from batch to continuous operation, Chemical Engineering Journal, 401 (2020) 126126, https://doi.org/10.1016/j.cej.2020.126126

58. Adriana Freites Aguilera, Jani Rahkila, Jarl Hemming, Maristiina Nurmi, Gaetan Torres, Théophile Razat, Pasi Tolvanen, Kari Eränen, Sébastien Leveneur, Tapio Salmi, Epoxidation of tall oil catalyzed by an ion exchange resin under conventional heating and microwave irradiation, Industrial & Engineering Chemistry Research, 59 (22) (2020) 10397–10406.

Open access https://doi.org/10.1021/acs.iecr.0c01288

57. Houda Ariba, Yanjun Wang, Christine Devouge-Boyer, Roumiana Stateva, Sébastien Leveneur, Physicochemical properties for the reaction systems: levulinic acid, its esters and γ-valerolactone, Journal of Chemical & Engineering Data, 65 (6) (2020) 3008-3020 https://dx.doi.org/10.1021/acs.jced.9b00965

Open access https://hal.archives-ouvertes.fr/hal-02904648v1

56. W. Y. Pérez-Sena, T. Salmi, L. Estel, S. Leveneur, Thermal risk assessment for the epoxidation of linseed oil by classical Prisleschajew epoxidation and by direct epoxidation by H2O2 on alumina, Journal of Thermal Analysis and Calorimetry, 140 (2020) 673–684.

DOI: 10.1007/s10973-019-08894-2.

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-02435565

2019

55. Mohammad Yaghoub Abdollahzadeh Jamalabadi, Rezvan Alamian, Wei-Mon Yan, S. Leveneur, M. Safdari Shadloo, Effects of nanoparticle enhanced lubricant films in thermal design of plain journal bearings at high Reynolds numbers, Symmetry 11(11) (2019) 1353.

Open access https://doi.org/10.3390/sym11111353

54. E. A. Garcia-Hernandez, C. Ribeiro Souza, L. Vernières-Hassimi, S. Leveneur, Kinetic modeling using temperature as an on-line measurement: Application to the hydrolysis of acetic anhydride, a revisited kinetic model, Thermochimica Acta, 682 (2019) 178409. https://doi.org/10.1016/j.tca.2019.178409

Open access https://hal.archives-ouvertes.fr/hal-02435541v1

53. A. Dakkoune, L. Vernieres-Hassimi, S. Leveneur, D. Lefebvre, L. Estel, Analysis of thermal runaway events in French chemical industry, Journal of Loss Prevention in the Process Industries, 62 (2019) 103938. https://doi.org/10.1016/j.jlp.2019.103938

52. A. Freites Aguilera, P. Tolvanen, Johan Wärnå, S. Leveneur, T. Salmi, Kinetics and reactor modelling of fatty acid epoxidation in the presence of heterogeneous catalyst, Chemical Engineering Journal 375 (2019) 121936. https://doi.org/10.1016/j.cej.2019.121936

51. A. Freites Aguilera, P. Tolvanen, A. Oger, K. Eränen, S. Leveneur, J.-P. Mikkola, T. Salmi, Screening of ion exchange resin catalysts for epoxidation of oleic acid under the influence of conventional and microwave heating, Journal of Chemical Technology & Biotechnology, 94(9) (2019) 3020-3031. https://doi.org/10.1002/jctb.6112

50. Y. Wang, M. Cipolletta, L. Vernières-Hassimi, V. Casson-Moreno S. Leveneur, Application of the concept of Linear Free Energy Relationships to the Hydrogenation of Levulinic acid and its corresponding esters, Chemical Engineering Journal, 374 (2019) 822–831. https://doi.org/10.1016/j.cej.2019.05.218

Open access https://hal.archives-ouvertes.fr/hal-02151602v1

49. A. Freites Aguilera, P. Tolvanen, K. Eränen, J. Wärnå, S. Leveneur, T. Marchant, T. Salmi, Kinetic modelling of Prileschajew epoxidation of oleic acid under conventional heating and microwave irradiation, Chemical Engineering Science, 199 (2019) 426-438. https://doi.org/10.1016/j.ces.2019.01.035

48. X. Cai, M. Matos, S. Leveneur, Structure-reactivity: comparison between the carbonation of epoxidized vegetable oils and the corresponding epoxidized fatty acid methyl ester, Industrial & Engineering Chemistry Research, 58 (2019) 1548-1560. https://doi.org/10.1021/acs.iecr.8b05510

Open access https://hal.archives-ouvertes.fr/hal-02151604v1

47. V. Casson-Moreno, A.-L. Garbetti, S. Leveneur, G. Antonioni, A consequences-based approach for the selection of relevant accident scenarios in emerging technologies, Safety Science, 112 (2019) 142–151. https://doi.org/10.1016/j.ssci.2018.10.024

46. B. Belgacem, S. Leveneur, M. Chlendi, L. Estel, M. Bagane, The aid of calorimetry for kinetic and thermal study: application to the dissolution of tunisian natural phosphates, Journal of Thermal Analysis and Calorimetry,135 (2019) 1891-1898, https://doi.org/10.1007/s10973-018-7157-3

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-02151606

2018

45. L. Vernieres-Hassimi, V. Casson-Moreno, M.-A. Abdelghani-Idrissi, S. Leveneur, Cooling configuration effect on the thermal risk of tubular reactor, Chemical Engineering Transactions, 67 (2018), DOI: 10.3303/CET1867008.

44. Y. Wang, L. Vernières-Hassimi, V. Casson-Moreno, J.-P. Hébert, S. Leveneur, Thermal risk assessment of levulinic acid hydrogenation to γ-valerolactone, Organic Process Research & Development, 22(9) (2018) 1092-1100. https://doi.org/10.1021/acs.oprd.8b00122

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-02435572

43. S. Leveneur, M. Pinchard, A. Rimbault, M. Safdari Shadloo, T. Meyer, Parameters affecting thermal risk through a kinetic model under adiabatic condition: Application to liquid-liquid reaction system, Thermochimica Acta, (2018) 10–17. https://doi.org/10.1016/j.tca.2018.05.024

Open access https://hal.archives-ouvertes.fr/hal-02127857

42. X. Cai, J.-L. Zheng, A. Freites Aguilera, L. Vernières-Hassimi, P. Tolvanen, T. Salmi, S. Leveneur, Influence of ring opening reactions on the kinetics of bio-based cottonseed oil epoxidation, International Journal of Chemical Kinetics, 50(10) (2018) 726-741. https://doi.org/10.1002/kin.21208

41. W. Y. Pérez-Sena, X. Cai, N. Kebir, L. Vernières-Hassimi, C. Serra, T. Salmi, S. Leveneur, Aminolysis of cyclic-carbonate vegetable oils as a non-isocyanate route for the synthesis of polyurethane: a kinetic and thermal study, Chemical Engineering Journal, 346 (2018) 271-280. https://doi.org/10.1016/j.cej.2018.04.028

Open access https://hal.archives-ouvertes.fr/hal-02298873

40. X. Cai, K. Ait Aissa, L. Estel, S. Leveneur, Investigation of the physicochemical properties for vegetable oils and their epoxidized and carbonated derivatives, Journal of Chemical & Engineering Data, 63(5) (2018) 1524-1533. https://doi.org/10.1021/acs.jced.7b01075

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-02435575

39. A. Dakkoune, L. Vernieres-Hassimi, S. Leveneur, D. Lefebvre, L. Estel, Fault detection in the green chemical process: Application to an exothermic reaction, Chemical Engineering Transactions, 67 (2018), DOI: 10.3303/CET1867007.

38. A. Freites Aguilera, P. Tolvanen, S. Heredia, M. González Muñoz, T. Samson, A. Oger, A. Verove, K. Eränen, S. Leveneur, J.-P. Mikkola, T. Salmi, Epoxidation of fatty acids and vegetable oils assisted by microwaves catalysed by a cation exchange resin, Industrial & Engineering Chemistry Research, 57(11) (2018) 3876-3886.

37. A. Dakkoune, L. Vernières-Hassimi, S. Leveneur, D. Lefebvre, L. Estel, Risk assessment of french chemical industry, Safety Science, 105 (2018) 77-85.

36. J.-L. Zheng, P. Tolvanen, B. Taouk, K. Eränen, S. Leveneur, T. Salmi, Synthesis of carbonated vegetable oils: investigation of microwave effect in a pressurized continuous-flow recycle batch reactor, Chemical Engineering Research and Design, 132 (2018) 9-18.

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-02138614

35. M.A. Abdelghani-Idrissi, S. Khalfallaoui, D. Seguin, L. Vernières-Hassimi, S. Leveneur. Solar Tracker for Enhancement of the Thermal Efficiency of Solar Water Heating System, Renewable Energy, 119 (2018) 79-94.

2017

34. L. Vernières-Hassimi, A. Dakkoune, L. Abdelouahed, L. Estel, S. Leveneur, Zero-order versus intrinsic kinetics for the determination of TMRad: Application to the decomposition of hydrogen peroxide, Industrial & Engineering Chemistry Research, 56 (2017) 13040-13049.

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-02435634

33. O. Jogunola, T. Salmi, S. Leveneur, J.-P. Mikkola, Complexation equilibria studies of alkyl formate hydrolysis in the presence of 1-butylimidazole, Thermochimica Acta, 652 (2017) 62-68.

32. S. Leveneur, Thermal safety assessment through the concept of structure-reactivity: application to vegetable oils valorization, Organic Process Research & Development, 21(4) (2017) 543-550.

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-03144820

31. L. Abdelouahed, S. Leveneur, L. Vernieres-Hassimi, L. Balland, B. Taouk, Comparative investigation for the determination of kinetic parameters for biomass pyrolysis by thermogravimetric analysis, Journal of Thermal Analysis and Calorimetry, 129 (2017) 1201–1213.

30. X. Cai, J.-L. Zheng, J. Wärnå, T. Salmi, B. Taouk, S. Leveneur, Influence of gas-liquid mass transfer on kinetic modeling: Carbonation of epoxidized vegetable oils, Chemical Engineering Journal, 313 (2017) 1168-1183.

2016

29. S. Leveneur, L. Vernières-Hassimi, T. Salmi, Mass & energy balances coupling in chemical reactors for a better understanding of thermal safety, Education for Chemical Engineers, 16 (2016) 17-28.

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-02435639

28. H. Rakotondramaro, J. Wärnå, L. Estel, T. Salmi, S. Leveneur, Cooling and stirring failure for semi-batch reactor: application to exothermic reactions in multiphase reactor, Journal of Loss Prevention in the Process Industries, 43 (2016) 147-157.

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-02435638

27. K. Ait aissa, J.L. Zheng, L. Estel, S. Leveneur, Thermal stability of epoxidized and carbonated vegetable oils, Organic Process Research & Development, 20(5) (2016) 948-953.

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-02435640

26. A. Freites Aguilera, P. Tolvanen, K. Eränen, S. Leveneur, T. Salmi, Epoxidation of oleic acid under conventional heating and microwave radiation, Chemical Engineering and Processing: Process Intensification, 102 (2016) 70–87.

25. F. Asherman, G. Cabot, C. Crua, L. Estel, C. Gagnepain, T. Lecerf, A. Ledoux, S. Leveneur, M. Lucereau, S. Maucorps, M. Ragot, J. Syrykh, M. Vige, Designing and demonstrating a master student project to explore carbon dioxide capture technology, Journal of Chemical Education, 93(4) (2016) 633-638.

Open access https://hal.archives-ouvertes.fr/hal-02328192

24. J.-L. Zheng, J. Wärnå, F. Burel, T. Salmi, B. Taouk, S. Leveneur, Kinetic modeling strategy for an exothermic multiphase reactor system: application to vegetable oils epoxidation by using Prileschajew method, AIChE Journal, 62(3) (2016) 726-741.

2015

23. L. Vernières-Hassimi, S. Leveneur, Alternative method to prevent thermal runaway in case of error on operating conditions in continuous reactor, Process Safety and Environmental Protection, 98 (2015) 365-373.

22. J.-L. Zheng, F. Burel, T. Salmi, B. Taouk, S. Leveneur, Carbonation of vegetable oils: influence of mass transfer on reaction kinetics, Industrial & Engineering Chemistry Research, 54(43) (2015) 10935-10944.

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-02138621

21. S. Leveneur, L. Estel, C. Crua, Thermal risks assessment of vegetable oil epoxidation, Journal of Thermal Analysis and Calorimetry, 122 (2015) 795–804.

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-02435644

20. B. Huang, S. Leveneur, T. Zamar, J.-P. Mikkola, B. Taouk, Towards production of γ-valerolactone via hydrogenation of aqueous levulinic acid, International Journal of Chemical Reactor Engineering, 13(1) (2015) 119–127.

2014

19. S. Leveneur, A. Ledoux, L. Estel, B. Taouk, T. Salmi, Epoxidation of vegetable oils under microwave irradiation, Chemical Engineering Research and Design, 92(8) (2014) 1495–1502.

18. S. Leveneur, F. Delannoy, Y. Levesqueau, J.-P. Hébert, L. Estel, B. Taouk, T. Salmi, The limit of DSC as a Preliminary Tool to Determine the Safety Parameters?, Chemical Engineering Transactions, 36,139-144 DOI: 10.3303/CET1436024

Open access https://www.cetjournal.it/index.php/cet/article/view/CET1436024

17. S. Leveneur, J. Zheng, B. Taouk, F. Burel, J. Wärnå, T. Salmi, Interaction of thermal and kinetic parameters for a liquid liquid reaction system: Application to vegetable oils epoxidation by peroxycarboxylic acid, Journal of the Taiwan Institute of Chemical Engineers, 45 (2014) 1449–1458.

2013

16. C. Gu, S. Leveneur, L. Estel, A. Yassine, Industrial Symbiosis Optimization Control Model for the exchanges of the material/energy flows in an industrial production park, IFAC Proceedings Volumes, 46(9) (2013) 1015-1020.

15. C. Gu, S. Leveneur, L. Estel, A. Yassine, Modeling and optimization of material/energy flow exchanges in an industrial park, Energy Procedia, 36 (2013) 243-252.

14. C. Gu, L. Estel, A. Yassine, S. Leveneur, A multiobjective optimization model for designing and optimizing an ecological industrial park, 2013 Ninth International Conference on Natural Computation (ICNC), (2013) 595–600. doi:10.1109/ICNC.2013.6818046.

2012

13. S. Leveneur, M. Thones, J.-P. Hébert, B. Taouk, T. Salmi, From Kinetic study to thermal safety assessment: application to peroxyformic acid synthesis, Industrial & Engineering Chemistry Research, 51(43) (2012) 13999–14007.

12. S. Leveneur, C. A. de Araujo Filho, L. Estel, T. Salmi, Modeling of a liquid-liquid-solid heterogeneous reaction system: application to the synthesis of peroxy fatty acids, Industrial & Engineering Chemistry Research, 51(1) (2012) 189–201.

2011

11. P. Tolvanen, A. Sorokin, P. Mäki-Arvela, S. Leveneur, D. Yu. Murzin, T. Salmi, Batch and semi-batch partial oxidation of starch by hydrogen peroxide in the presence of iron tetrasulfophthalocyanine catalyst: the effect of ultrasound and catalyst addition policy, Industrial & Engineering Chemistry Research, 50 (2) (2011) 749-757. https://doi.org/10.1021/ie100868k

10. S. Leveneur, J. Wärnå, K. Eränen, T. Salmi, Green process technology for peroxycarboxylic acids: estimation of kinetic and dispersion parameters aided by RTD measurements: green synthesis of peroxycarboxylic acids, Chemical Engineering Science, 66 (2011) 1038–1050. https://doi.org/10.1016/j.ces.2010.12.005

9. O. Jogunola, T. Salmi, J. Warna, S. Leveneur, J.P. Mikkola, Modelling of Simultaneous Reaction and Diffusion in Chemical Reactors with Particle Size Distributions: Application of Ion-exchange Resins in Heterogeneous Catalysis, Chemical Engineering Transactions, 24 (2011) 139-144

Open access https://folk.ntnu.no/skoge/prost/proceedings/pres2011-and-icheap10/ICheaP10/7Jogunola.pdf

2010

8. H. Koskinen, S. Leveneur, A. Sundquist, N. Musakka, T.Salmi, I. Renvall Functionality of Poly(α-hydroxyacrylic acid) as H2O2 stabilizing agent, Oxidation Communication, Book 2 (2010) 258-274.

7. S. Leveneur, N. Kumar, D. Yu. Murzin, T. Salmi, Stability of hydrogen peroxide during perhydrolysis of carboxylic acids on acidic heterogeneous catalysts, Research on Chemical Intermediates, 36(4) (2010) 389-401. https://doi.org/10.1007/s11164-010-0149-y

6. S. Leveneur, J. Wärnå, T. Salmi, D. Yu. Murzin, A review: Catalytic synthesis and decomposition of peroxycarboxylic acids, Trends in chemical engineering, 13 (2010) 17-52.

2009

5. S. Leveneur, J. Wärnå, T. Salmi, D. Yu. Murzin, L. Estel, Interaction of Intrinsic Kinetics and Internal Mass Transfer in Porous Ion-Exchange Catalysts: Green Synthesis of Peroxycarboxylic Acids, Chemical Engineering Science, 64(19) (2009) 4104-4114.

4. S. Leveneur, D. Yu. Murzin, T. Salmi, J.-P. Mikkola, N. Kumar, K. Eränen, L. Estel, Synthesis of Peroxypropionic Acid from Propionic Acid and Hydrogen Peroxide using heterogenous Catalysts, Chemical Engineering Journal, 147 (2009) 323-329.

3. S. Leveneur, D. Yu. Murzin, T. Salmi, Application of Linear Free-Energy Relations to Perhydrolysis of Different Carboxylic Acids over Homogeneous and Heterogeneous Catalysts, Journal of Molecular Catalysis A: Chemical, 303 (2009) 148-155.

2008

2. S. Leveneur, T. Salmi, D. Yu. Murzin, L. Estel, J. Wärnå, N. Musakka, Kinetic Study and Modeling of Peroxypropionic Acid Synthesis from Propionic Acid and Hydrogen Peroxide using Homogeneous Catalysts, Industrial & Engineering Chemistry Research, 47(3) (2008) 656-664.

2007

1. S. Leveneur, T. Salmi, N. Musakka, J. Wärnå, Kinetic Study of Decomposition of Peroxypropionic acid in Liquid-Phase through Direct Analysis of Decomposition Products in Gas Phase, Chemical Engineering Science, 62 (18-20) (2007) 5007-5012.

- INSA Rouen Normandie

- Åbo Akademi University

- Région Normandie

- European Regional Development Fund

- Interreg

- ANR-DFG

- Academy of Finland

- Industry (KEMIRA, ARKEMA,…)

- Campus France

Postdoctoral Research Associate

- Keltouama AIT AÏSSA (2015)

- Pasi TOLVANEN (2014)

- Botao HUANG (2013)

PhD Students

- Yudong MENG (2021-2025) "Structure & Reactivity apprοach applied tο the epοxidatiοn οf vegetable οils"

Open access https://theses.fr/s392128 - Sindi BACO (2021-2024) "Synergic use of Linear Free Energy Relationships and PC-SAFT"

Open access https://theses.fr/s392122 - Wenel Naudy VASQUEZ SALCEDO (2021-2024) “Bio Jet Fuels Production from Lignocellulosic Biomass"

Open access https://theses.fr/s392233 - Alexandre CORDIER (2021-2023) “Valorisation de l’acide lévulinique par microfluidique : approches théoriques et expérimentales”

Open access https://www.theses.fr/s263533 - Daniele DI MENNO DI BUCCHIANICO (2020-2023) “Development of processes for the valorization of lignocellulosic

biomass from renewable energy sources”

Open access https://www.theses.fr/s260584 - José DELGADO (2020-2023) "Production of GVL, a green platform molecule"

Open access https://www.theses.fr/s241864 - Xiaojia LU (2017-2021) "Reductive catalytic depolymerization of industrial lignin and hemicellulose – process development and intensification"

Open access https://www.doria.fi/handle/10024/181798?locale=lfi - Wander Yamil PEREZ SENA (2017-2021) "Monomers from vegetable oil feedstock : kinetics, catalysis and thermal risk"

Open access https://www.doria.fi/handle/10024/181513 - Elizabeth GARCIA-HERNANDEZ (2017-2020) "Global sensitivity analysis applied to thermal risk evaluation"

Open access http://www.theses.fr/en/2020NORMIR10 - Yanjun WANG (2017-2020) "Production of γ-valerolactone from the hydrogenation of levulinic acid or alkyl levulinates : calorimetry and kinetic study"

Open access http://www.theses.fr/en/2020NORMIR02 - Adriana FREITES AGUILLERA (2016-2020) "Epoxidation of vegetable oils : process intensification for biomass conversion"

Open access https://www.doria.fi/handle/10024/175243 - Xiaoshuang CAI (2016-2019) "Production of carbonated vegetable oils from a kinetic modeling to a structure-reactivity approach"

Open access http://www.theses.fr/2019NORMIR05 - Suttiya CHIEWUDOMRAT (2015-2018) "Optical characterization of gradient in droplets : application to CO2 capture by MEA spray"

- Jun Liu ZHENG (2013-2016) "Development of a process for the epoxidation and carbonation vegetable oils : application to cottonseed oil"

Open access http://www.theses.fr/en/2016ISAM0006 - Chao GU (2011-2014) "Creating an inductive model of growing industrial clusters with optimized flows, to reduce their impact on the environment"

Visiting researchers

- Gilberto BRANQUINHO FERNANDES (Universidade Federal de São Carlos, 2024)

- Elano NERY Brazilian PhD student (PGQUIM - UFC, 2023)

- Giordano EMRYS SCARPONI, Professor (University of Bologna, Italy, 2022)

- Viktoria Flora CSENDES, Bachelor student (University of Pannonia, Hungary, 2021)

- Daniel Datch MEFOUET ABESSOLO, PhD student (Ecole Normale Supérieure de Libreville, Gabon, 2020)

- Andrés Felipe GUZMÁN AGUDELO, PhD student (University of Antioquia, Colombia, 2019)

- Valeria CASSON MORENO, Professor (University of Bologna, Italy, 2017)

- Balsam BELGACEM, PhD student (University of Gabès, Tunisia, 2014)

Master Students

- Kanugala Watthage Shakila DILLSHY PERERA (2024)

- Laura BERNACCHIONI (2023)

- Erny Encarnacion MUNOZ (2022)

- Antonella CIPOLLA (2021)

- Rashid Ismail BEDAWI ZAKARIA (2021)

- Wenel Naudy VASQUEZ SALCEDO (2021)

- Sindi BACCO (2020)

- Giulia BRONZETTI (2020)

- Daniele DI MENNO DI BUCCHIANICO (2019)

- Sarah CAPECCI (2019)

- Houda ARIBA (2019)

- Mariasole CIPOLLETTA (2018)

- Masoud KHALILPOURSHIRAZ (2018)

- Anna Laura GAREBETTI (2017)

- Wander Y. PÉREZ-SENA (2017)

- Helisoa RAKOTONDRAMARO (2014)

- Adriana FREITES AGUILLERA (2014)

- Tamara ZAMAR (2012)

- Federico SAFATLE (2012)

- Claire LEBLAY (2012)

- P. G. MENDONÇA MILEO (2011)

- Jun Liu ZHENG (2011)

- C. A. DE ARAUJO FILHO (2010)

From the 10th to the 12th of December, INSA Rouen organized a workshop on Research, Innovation and Citizen&Science Workshop. The objectives of the workshop were to enlarge the contacts in the field of chemical reaction engineering, focusing on high-tech innovations in reaction and separation technologies (use of milli- and microreactor technologies, 3D-printing of reactor and catalyst structures, application of ultrasound, microwave and plasma technology in reaction engineering, development of novel separation technologies, such as chromatography and membrane technology). The applications were focused mainly on valorizing components in biomass to chemicals and fuel components, and using renewable energy. The topic of science and society was also be treated as how to engage citizen in science.

We gathered 40 researchers from PhD students to full researchers and professors. Big thanks to Maria Pereira for her help.

I want to thank all the participants and the lecturers: Tapio Salmi from Åbo Akademi University, Tuomas Koiranen from LUT University, Carine Julcour from Toulouse INP - Institut National Polytechnique de Toulouse, Igor Plazl from University of Ljubljana, Tommaso Cogliano from Åbo Akademi University, Kyllian Neveu from Université de Rouen Normandie, German Araujo from Åbo Akademi University, Yudong MENG from Institut national des Sciences appliquées de Rouen, Lujie Shi from Institut national des Sciences appliquées de Rouen, Francesco Sandri from Åbo Akademi University, Marie-Christine Fournier-Salaun from Université de Rouen Normandie, Polona Žnidaršič-Plazl from University of Ljubljana, Attila Egedy from Pannon Egyetem - University of Pannonia, Flora Viktoria Csendes from Institut national des Sciences appliquées de Rouen, José Emilio Delgado Liriano from INSA Rouen Normandie, Hung Nguyen from LUT University, Laszlo Balogh from Pannon Egyetem - University of Pannonia and Michalis Lianos from Université de Rouen Normandie

We (Tapio Salmi and sebastien leveneur) thank Programme Maupertuis, Région Normandie, Institut national des Sciences appliquées de Rouen, Métropole Rouen Normandie via #PROMETEE project and Fédération IEPE for their financial supports allowing scientific and friendly exchanges.

February 2022-February 2025: Rouen’s project PROMETEE (Processes to valoRize nOrman bioMass from renEwable energies: ciTizen sciencE and process safEty)

Consortium: Aoues’s team (INSA Rouen) for the mechanical and civil engineering part, Liano’s team (Rouen university) for the citizen science part and Leveneur’s team for process safety.

Total budget : 120 k€.

Climate emergency and citizen distrust push us to re-think (re-design) the different models of environmental transition. Nowadays, interdisciplinary collaboration between engineering and social sciences is mandatory to find alternative and acceptable solutions.

Valorization of lignocellulosic biomass by renewable energy such as green hydrogen will sustain our chemical industries and contribute to the mix energy. Such processes could lead to new industrial risks that must be identified and evaluated by new methods.

Researchers from Rouen University and INSA Rouen Normandy concluded that industrial projects involving these processes must be evaluated on the innovative tetraptic Society-Industrial Risk-Environmental impact-Cost evaluation.

Lignocellulosic biomass from agricultural waste can be valorized into different chemicals, fuels and materials. These different options can affect the cost evaluation, environment or industrial risk assessment differently. Citizens will also evaluate these options by using/testing/developing different protocols.

Principal investigators: Sébastien Leveneur (INSA Rouen Normandie) & Michalis Lianos (Rouen University).

SCIENTIFIC RESULTS

NEWSPAPER

1. Paris-Normandie, 24th of September 2022: "À Rouen, des chercheurs lancent un appel aux volontaires pour construire une science citoyenne"

PUBLICATIONS

1. Wenel Naudy Vásquez Salcedo, Bruno Renou, Sébastien Leveneur, Thermal Stability for the Continuous Production of γ-valerolactone from the hydrogenation of n-butyl levulinate in a CSTR, Processes, https://doi.org/10.3390/pr11010237

Open access: https://doi.org/10.3390/pr11010237

2. S Leveneur, Kinetic modeling: Regression and validation stages, a compulsory tandem for kinetic model assessment, The Canadian Journal of Chemical Engineering, 2023;101:7078–7101 https://doi.org/10.1002/cjce.24956

3. Sébastien Leveneur, Combining isothermal and adiabatic mode experiments for kinetic constants estimation: application to the hydrogenation of 5-(hydroxymethyl)furfural (5-HMF), Industrial & Engineering Chemistry Research, https://doi.org/10.1021/acs.iecr.3c04346

4. Viktória Flóra Csendes, Shakila Perera, Christine Devouge-Boyer, Mélanie Mignot, Karine Thomas, Sébastien Leveneur, Enhanced Butyl Levulinate Synthesis from Cellulose under High-Gravity Conditions: Catalyst and Solvent Optimization, Renewable Energy, Volume 250, September 2025, 123298, https://doi.org/10.1016/j.renene.2025.123298

HAL https://hal.science/view/index/docid/5060480

CONFERENCES

1. Wenel Naudy Vasquez Salcedo, Bruno Renou, Sebastien Leveneur, Gamma-valerolactone production from butyl levulinate: advance kinetic modeling and thermal risk assessment.

Oral presentation at Calorimetry and Thermal analysis JCAT52, June 15-17, 2022, Colmar, France

2. S. Leveneur, “Valorisation of vegetable oils: from thermal risk assessment to kinetic modelling”

Keynote lecture at 26th International Congress of Chemical and Process Engineering CHISA, 21st-25th, August 2022, Prague, Czech Republic

January 2022-November 2022: French embassy project with Indonesia POTION (Production sûr de biOcarburant aviatTION : une approche expérimentale et théorique Safe production of aviation biofuel: experimental and theoretical approaches).

Principal investigator (Leveneur) of POTION, which is in collaboration with Dr. Mohammad Kemal Agusta CMD-QE Bandung Institute of Technology for DFT calculation. The objective of this project is to have a better understanding of the production of aviation fuel from lignocellulosic biomass.

SCIENTIFIC RESULTS

CONFERENCES

1. Wenel Naudy Vasquez Salcedo, Jose Delgado, Henrik Grenman, Mohammad Kemal Agusta, Bruno Renou, Sebastien Leveneur, Gamma-valerolactone: promissing intermediate for bio jet fuel.

Oral presentation for WasteEng22, 9th International Conference on Engineering for Waste and Biomass Valorisation, June 27-30 2022, Copenhagen, Denmark

February 2021-July 2024: ANR-DFG project MUST: MicroflUidics for Structure-reactivity relationships aided by Thermodynamics & kinetics.

Researchers: Sébastien Leveneur (Coordinator, INSA Rouen Normandie), Julien Legros (COBRA, Université de Rouen) and Christoph Held (Dortmund TU, Germany).

Ph.D. students: Sindi Baco, Alexandre Cordier and Marcel Klinksiek

Total budget: 600k€ including 3 Ph.D. salaries.

ANR-20-CE92-0002 & Deutsche Forschungsgemeinschaft (DFG) - Project number 446436621

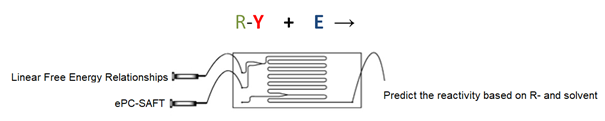

The relationships between the structure of chemicals (reactants or products) and their reactivity (kinetics and thermodynamics) is a research area that crosslinks thermodynamics, kinetics, organic chemistry and chemical engineering. This project will investigate this research area by German and French specialists. The concept of Linear Free Energy Relationships (LFER), including the Taft equation, is a powerful structure-reactivity tool that accounts for steric, polar and resonance effects on a series of chemical reactions. Taft equation shows that there is a relationship between the structure of reactants (i.e., the substituent near to the reaction center) and their reactivities within a reaction series. It is state-of-the-art to apply this to chemical reactions (e.g. esterification), and it is claimed that the developed parameters are valid independent of the reaction conditions. However, mainly esterification and hydrolysis reactions were used in one kind of solvent, which in principle limits the general validity of the relationships. Thus, generalizing LFER concepts to vast number of solvents or solvent mixtures and even to multiphase reaction systems requires intrinsic kinetic profiles in the absence of concentration and temperature gradients, expressed in terms of thermodynamic activities. This will be developed in this project.

The redeveloped Taft-based method will be mainly applied to three chemical reaction systems that involve lignocellulosic-derived platform molecules: 1) glucose solvolysis to levulinate ester using different alcohol solvents, 2) esterification-hydrolysis of levulinic acid-levulinate ester and

3) hydrogenation of levulinic acid or levulinate ester to gamma-valerolactone by H2 and solid catalyst. We will vary the reactants for these systems, i.e., different alcohols for 1) and 2), and different levulinate esters for 3). System 2) will prove the validity of the LFER concept to enzyme catalysis. The goal is to use the redeveloped method to study and predict the -R substituent effect in the reactant and the solvent effect on kinetic profiles.

Reaching the goal requires different research expertise. The use of microfluidic technologies will allow performing kinetic experiments avoiding transport limitations. Activities of the reactants and products will be predicted based on the experimental kinetic profiles and the equation of state ‘ePC-SAFT’. This will ultimately allow predicting reaction properties (standard enthalpies, standard Gibbs energies) as well as intrinsic activity-based reaction kinetic constants. Furthermore, ePC SAFT will be used to predict the required phase behavior of the reaction systems (e.g. H2 solubility in reaction medium); all predictions (phase behavior and reaction characteristics) will be validated by experiments.

The association of both methods –LFER & ePC-SAFT– will mean a significant new understanding and a new dimension in designing chemical syntheses.

Another short movie on MUST (in French)

DOCTORAL THESIS DEFENCE

1. Sindi BACO (April 2021-October 2024) “Synergic use of Linear Free Energy Relationships and PC-SAFT”

Open access https://theses.fr/s392122

Jury’s member: Ernesto Salzano (University of Bologna), Dmitry Murzin (Åbo Akademi), Blaz Likozar (University of Ljubljana), Romain Privat (Université de Lorraine), Claire Bordes (Université C. Bernard Lyon 1)

Supervisor: Sébastien Leveneur, Christoph Held, Julien Legros

2. Alexandre CORDIER (2021-2023) “Valorisation de l’acide lévulinique par microfluidique : approches théoriques et expérimentales”

Open access https://www.theses.fr/s263533

From February 2021 to December 2023, I got the pleasure of following the work of Alexandre Cordier on the valorization of levulinic acid in microfluidic systems in the framework of ANR DFG

Alexandre Cordier made the challenge to defend in 34 months with two publications, and to work at the interface chemistry-chemical engineering.

Thanks to Julien Legros and Laetitia Chausset-Boissarie for their supervision, and gathering a nice jury: Catherine Gomez, Jean-François Portha, Isabelle Chataigner, Benoît Crousse, Mael PENHOAT

MASTER THESIS DEFENCE

1. July 2021, Wenel Naudy VASQUEZ SALCEDO “Calorimetry study of the hydrogenation of alky levulinates”

2. July 2022, Erny ENCARNACION MUNOZ “Structure-reactivity for the production of alkyl levulinates from fructose”

1. Jose Delgado, Wenel Naudy Vasquez Salcedo, Giulia Bronzetti, Valeria Casson Moreno, Mélanie Mignot, Julien Legros, Christoph Held, Henrik Grénman, Sébastien Leveneur, Synergy effect of dual catalysts for the synthesis of γ-valerolactone from n-butyl levulinate hydrogenation over Ru/C and Amberlite IR-120, Chemical Engineering Journal, Volume 430, Part 3, 15 February 2022, 133053, https://doi.org/10.1016/j.cej.2021.133053.

Open access https://hal.archives-ouvertes.fr/hal-03498093

2. Sindi Baco; Marcel Klinksiek; Rashid Ismail Bedawi Zakaria; Elizabeth Antonia García Hernandez; Melanie Mignot; Julien Legros; Christoph Held; Valeria Casson Morena; sebastien leveneur, Chemical Engineering Science, Volume 260, 12 October 2022, 117928, DOI https://doi.org/10.1016/j.ces.2022.117928

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-03735962

3. Alexandre Cordier, Marcel Klinksiek, Christoph Held, Julien Legros, Sébastien Leveneur, Biocatalyst and continuous microfluidic reactor for an intensified production of n-butyl levulinate: kinetic model assessment, Chemical Engineering Journal, Volume 451, Part 1, 1 January 2023, 138541, https://doi.org/10.1016/j.cej.2022.138541

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-03748632

4.Marcel Klinksiek, Sindi Baco, Sébastien Leveneur, Julien Legros, Christoph Held, Activity-based models to predict kinetics of levulinic acid esterification, ChemPhysChem, https://doi.org/10.1002/cphc.202200729

Open access: https://hal.science/hal-03825917

5. Jose Delgado, Wenel Naudy Vasquez Salcedo, Christine Devouge-Boyer, Jean-Pierre Hebert, Julien Legros, Bruno Renou, Christoph Held, Henrik Grenman, Sébastien Leveneur, Reaction enthalpies for the hydrogenation of alkyl levulinates and levulinic acid on Ru/C– influence of experimental conditions and alkyl chain length, Process Safety and Environmental Protection, https://doi.org/10.1016/j.psep.2023.01.025

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-03935524

6. Sindi Baco, Marcel Klinksiek, Mélanie Mignot, Christoph Held, Julien Legros, and Sébastien Leveneur, Temperature effect on the steric and polar Taft substituent parameter values, Reaction Chemistry & Engineering, https://doi.org/10.1039/D3RE00500C

7. Erny Encarnacion Munoz, Daniele Di Menno Di Bucchianico, Christine Devouge-Boyer, Julien Legros, Christoph Held, Jean-Christophe Buvat, Valeria Casson Moreno, Sébastien Leveneur, Combination of linear solvation energy and linear free-energy relationships to aid the prediction of reaction kinetics: application to the solvolysis of 5-HMF by alcohol to levulinate, Chemical Engineering Research and Design, Volume 205, May 2024, Pages 312-323, https://doi.org/10.1016/j.cherd.2024.03.040

Open access: https://hal.science/hal-04527410 & https://doi.org/10.1016/j.cherd.2024.03.040

8. Iman Bahrabadi Jovein, Sindi Baco, Gabriele Sadowski, Ferruccio Doghieri, Ferruccio Doghieri, Marco Giacinti Baschetti, Gangqiang Yu, Sébastien Leveneur, Julien Legros, Christoph Held, Comprehensive Compilation on Esterification Reactions and Predicting Reaction Kinetics and Equilibrium Using PC-SAFT, ACS Engineering Au, https://doi.org/10.1021/acsengineeringau.5c00002

HAL https://hal.science/hal-05018931

9. Marcel, Klinksiek; Sindi, Baco; Sebastien, Leveneur; Julien, Legros; Christoph, Held, Predicting proton activity and acid dissociation equilibria in mixed-solvent systems, and their impact on esterification kinetics of levulinic acid, Industrial And Engineering Chemistry Research, 64, 11, 6188–6202, https://doi.org/10.1021/acs.iecr.5c00115

HAL https://hal.science/hal-04986610

CONFERENCES

Oral presentation

1. Oral communication for The International Symposium on Green Chemistry (ISGC2022), May 16TH - 20TH, 2022, La Rochelle, France.

Jose Delgado, Wenel Naudy Vasquez Salcedo, Christoph Held, Henrik Grénman, Sébastien Leveneur, Adiabatic hydrogenation of Alkyl Levulinates to Gamma-valerolactone.

2. Oral communication for The International Symposium on Green Chemistry (ISGC2022), May 16TH - 20TH, 2022, La Rochelle, France.

Alexandre Cordier, Christoph Held, Julien Legros, Sebastien Leveneur, Enzymatic catalysis of butyl levulinate synthesis in continuous microfluidic system: kinetic model assessment.

3. Sindi Baco, Alexandre Cordier, Christoph Held, Julien Legros, Sebastien Leveneur, Enzymatic esterification of levulinic acid in continuous microfluidic system.

Oral presentation for WasteEng22, 9th International Conference on Engineering for Waste and Biomass Valorisation, June 27-30 2022, Copenhagen, Denmark

4. S. Baco, M. Klinksiek, R. I. B. Zakaria, E. A. Garcia Hernandez, M. Mignot, J. Legros, C. Held, V. Casson Moreno, S. Leveneur, Solvent effect investigation on the acid esterification of levulinic acid by ethanol throughout a kinetic and thermodynamic combined approach.

Oral presentation for 26th International Congress of Chemical and Process Engineering CHISA, 21st-25th, August 2022, Prague, Czech Republic

5.Cordier A., Legros J., Held C., Leveneur S, "Predictive model of the biocatalytic synthesis of butyl levulinate from levulinic acid in a continuous flow microreactor"

Oral presentation 9th IUPAC International Conference on Green Chemistry ICGC, Athena (Greece), 5-9 September 2022

6. M. Klinksiek, C. Held, "Thermodynamics-assisted kinetic model for esterification reactions based on ePC-SAFT: Application to levulinic acid"

Oral presentation ESAT2024, 33rd European Symposium on Applied Thermodynamics 2024, Edinburgh, UK, 9-12 June 2024

7. E. Encarnacion Munoz, J.C. Buvat, S. Leveneur, Kinetic modeling aided by structure reactivity relationships applied to the solvolysis of fructose into 5-RMF and alkyl levulinates.

Oral communication for The International Symposium on Green Chemistry (ISGC2025), May 12TH - 16TH, 2025, La Rochelle, France.

Keynote lectures

1.S. Leveneur, "From kinetic model to process simulation: production of levulinate",

Keynote lecture at CAMURE 12 & ISMR 11, 8th-11th of September 2024, Ghent, Belgium

2.S. Leveneur, "Combining isothermal and adiabatic mode experiments for kinetic constants estimation: application to the hydrogenation of 5-HMF"

Keynote lecture at 27th International Congress of Chemical and Process Engineering CHISA, 25th-29th, August 2024, Prague, Czech Republic

Poster presentation

1. Sindi Baco, Julien Legros, Christoph Held, Sébastien Leveneur, Combination of PC-SAFT and Taft equation to predict the effect of solvent and reactant on esterification reaction

Poster presentation ESAT2024, 33rd European Symposium on Applied Thermodynamics 2024, Edinburgh, UK, 9-12 June 2024

December 2021-December 2024: Normandy’s region project ARBRE (Risk Analysis to processes valorizing 2nd generation biomass and using Renewable energies.

Consortium: Aoues’s team (INSA Rouen) for the mechanical and civil engineering part, Diarrassouba’s team (Le Havre university) for the logistic study (biomass transportation), Lefebvre’s team (Le Havre university) for the prognostic and detection study, Maugé’s team (CNRS Caen) for the catalyst development, Aubert’s team (Rouen university) for the ecology impact and Leveneur’s team for chemical process.

Coordinator: S Leveneur.

Total budget: 574 k€

Scientific presentation

The ARBRE project aims to develop a process for the valorization of Normandy's lignocellulosic biomass (e.g. dedicated cultivation such as beech or agricultural waste such as flax shives) by using green hydrogen obtained from wind energy. The chemical process studied will be the Reductive Catalytic Fractionation (RCF) process of lignocellulosic biomass.

This project ultimately aims to make an economic and risk assessment of this industry. Indeed, such chemical plants can present new risks.

RISK -Evaluate the risks of dust explosion (lignocellulosic biomass) and thermal runaway -Establish a method for assessing technological and natural risks based on a probabilistic approach -Establish safety barriers and integrate these risks during the design phase (early-conception approach).

SAFETY -Develop decision-making tools for prevention by detection and early diagnosis -Use artificial intelligence approaches for fault diagnosis

LOGISTICS -Mathematical model (s) to optimize flow exchanges between biomass (production, harvest, transport and considering the seasonality of biomass), hydrogen ("seasonality" of wind power production) and RCF process.

ECOLOGICAL Evaluate the impact of dedicated crops on soils

PROCESS ENGINEERING & CATALYSIS -Develop kinetic and thermodynamic models -Synthesize and characterize heterogeneous catalysts for the RCF process -Develop a Process Flow Diagram associated with lignocellulosic biomass valuation processes -Perform an economic evaluation in strong interaction with the logistics objectives (including security barriers)

SEMINAR IN OCTOBER 2022

DOCTORAL THESIS DEFENCE

1. Daniele DI MENNO DI BUCCHIANICO (2020-2023) “Development of processes for the valorization of lignocellulosic

biomass from renewable energy sources” https://www.theses.fr/s260584

Daniele successfully defended his doctoral thesis the 18th of October 2023. In three years, he developed different processes for the production of levulinates and gamma-valerolactone, including kinetic model, cost, environmental and risk assessments.

This doctoral thesis was done in the framework of #arbreproject funded by Région Normandie and ERDF. This thesis was done in joint degree between Institut national des Sciences appliquées de Rouen and University of Bologna (Alma Mater Studiorum – Università di Bologna).

We thank all jury's member for this moment: Catherine AZZARO PANTEL, Joris Thybaut, Eric Schaer, Nadine Gabas and Sophie THIEBAUD-ROUX

SCIENTIFIC RESULTS

1.Daniele Di Menno Di Bucchianico, Yanjun Wang, Jean-Christophe Buvat, Yong Pan, Valeria Casson Moreno, Sébastien Leveneur, Production of levulinic acid and alkyl levulinates: A process insight, Green Chemistry, 2022, 24, 614–646. https://doi.org/10.1039/D1GC02457D

Open access https://hal.archives-ouvertes.fr/hal-03498103

2.Daniele Di Menno Di Bucchianico, Jean-Christophe Buvat, Mélanie Mignot, Valeria Casson Moreno and Sébastien Leveneur, Role of solvent the production of butyl levulinate from fructose, Fuel, Volume 318, 15 June 2022, 123703, https://doi.org/10.1016/j.fuel.2022.123703.

Open access https://hal-normandie-univ.archives-ouvertes.fr/hal-0359835c0

3. Daniele Di Menno Di Bucchianico, Antonella Cipolla, Jean-Christophe Buvat, Mélanie Mignot, Valeria Casson Moreno, Sébastien Leveneur, Kinetic Study and Model Assessment for n-Butyl Levulinate Production from Alcoholysis of 5-(Hydroxymethyl)furfural over Amberlite IR-120, Industrial & Engineering Chemistry Research, 2022, 61, 30, 10818–10836, https://doi.org/10.1021/acs.iecr.2c01640

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-03731262

4. Yudong Meng, Nasreddine Kebir, Xiaoshuang Cai and Sebastien Leveneur, In-depth kinetic modeling and chemical analysis for the epox-idation of vegetable oils in a liquid-liquid-solid system, Catalysts 2023, 13, 274. https://doi.org/10.3390/catal13020274

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-03957361

5. Daniele Di Menno Di Bucchianico, Mélanie Mignot, Jean-Christophe Buvat, Valeria Casson Moreno, Sébastien Leveneur, Production of butyl levulinate from the solvolysis of high-gravity fructose over heterogeneous catalyst: in-depth kinetic modeling, Chemical Engineering Journal, Volume 465, 1 June 2023, 142914, https://doi.org/10.1016/j.cej.2023.142914

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-04066613

6. Wenel Naudy Vásquez Salcedo, Mélanie Mignot, Bruno Renou, Sébastien Leveneur, Assessment of kinetic models for the production of γ-valerolactone developed in isothermal, adiabatic and isoperibolic conditions, Fuel, Volume 350, 15 October 2023, 128792; https://doi.org/10.1016/j.fuel.2023.128792

Open access: https://hal-normandie-univ.archives-ouvertes.fr/hal-04115376

7. Yudong Meng, Nasreddine Kebir, Sebastien Leveneur, Reactivity and Structure: Epoxidation of Cottonseed Oil and the Corresponding Fatty Acid Methyl Ester, Biomass Conversion and Biorefinery, https://doi.org/10.1007/s13399-023-04985-1

Open access: https://normandie-univ.hal.science/hal-04245671

8. Lujie Shi, Younes Aoues, Sébastien Leveneur, Impact of aleatory and epistemic uncertainties on thermal risk and production assessment: application to the hydrogenation of levulinic acid and butyl levulinate, Journal of Loss Prevention in the Process industries, https://doi.org/10.1016/j.jlp.2024.105317

Open access: https://doi.org/10.1016/j.jlp.2024.105317 & https://hal.science/hal-04548473

9. Daniele Di Menno Di Bucchianico, Giordano Emrys Scarponi, Jean-Christophe Buvat, Sébastien Leveneur, Valeria Casson-Moreno, From biomass-derived fructose to γ-valerolactone: process design and technoeconomic assessment, Bioresource Technology, https://doi.org/10.1016/j.biortech.2024.130753

Open access: https://hal.science/hal-04563031

10. Lujie Shi, Younes Aoues, Valeria Casson-Moreno, Yankai Wang, Sébastien Leveneur Surrogate modeling-based uncertainties analysis for the determination of safe and optimal operating conditions in batch reactor, Computers & Chemical Engineering, Volume 192, January 2025, 108909, https://doi.org/10.1016/j.compchemeng.2024.108909

Open access: https://doi.org/10.1016/j.compchemeng.2024.108909 & https://hal.science/hal-04762703

11. Daniele Di Menno Di Bucchianico, Giordano Emrys Scarponi, Jean-Christophe Buvat, Sébastien Leveneur, Valeria Casson-Moreno, Sustainable design of biomass valorization processes for the production of gamma-valerolactone integrating wind energy and green hydrogen, Journal of Cleaner Production, Volume 491, 1 February 2025, 144829. https://doi.org/10.1016/j.jclepro.2025.144829

Open access: https://hal.science/hal-04905885

12. Viktória Flóra Csendes, Shakila Perera, Christine Devouge-Boyer, Mélanie Mignot, Karine Thomas, Sébastien Leveneur, Enhanced Butyl Levulinate Synthesis from Cellulose under High-Gravity Conditions: Catalyst and Solvent Optimization, Renewable Energy, Volume 250, September 2025, 123298, https://doi.org/10.1016/j.renene.2025.123298

HAL https://hal.science/view/index/docid/5060480

13. Daniel Edumujeze; Marie-Christine Fournier-Salaun; Sebastien Leveneur, Production of furfural: from kinetics to process assessment, Fuel, Volume 381, Part B, 1 February 2025, 133423. https://doi.org/10.1016/j.fuel.2024.133423

Open access: https://hal.science/hal-04744561 or https://doi.org/10.1016/j.fuel.2024.133423

CONFERENCES

1.Oral communication for The International Symposium on Green Chemistry (ISGC2022), May 16TH - 20TH, 2022, La Rochelle, France.

D. Di Menno Di Bucchianico, J.C. Buvat, V. Casson Moreno, S. Leveneur, Inside the mechanism for transforming cellulose into biofuels: kinetic and calorimetry investigation of 5-hmf alcoholysis to n-butyl levulinate over solid catalyst.

2. D. Di Menno Di Bucchianico, J.C. Buvat, V. Casson-Moreno, S. Leveneur, Kinetic modeling of fructose solvolysis to n-butyl levulinate in gamma-valerolactone as co-solvent.

Oral presentation for WasteEng22, 9th International Conference on Engineering for Waste and Biomass Valorisation, June 27-30 2022, Copenhagen, Denmark

3. D. Di Menno Di Bucchianico, A. Cipolla, J.C. Buvat, V. Casson Moreno, S. Leveneur, “Kinetic model assessment for the n-butyl levulinate production from the alcoholysis of 5-HMF.

Oral presentation for 26th International Congress of Chemical and Process Engineering CHISA, 21st-25th, August 2022, Prague, Czech Republic

4.D. Di Menno Di Bucchianico, J.C. Buvat, V. Casson Moreno, S. Leveneur, Biofuel candidate n-butyl levulinate from fructose solvolysis: Detailed kinetic investigation under high gravity conditions.

Oral presentation for the 15th Mediterranean Congress in Chemical Engineering, MECCE 2023, 30 May-2 June 2023, Barcelona, Spain.

5.D. Di Menno Di Bucchianico, J.C. Buvat, V. Casson Moreno, S. Leveneur, High-gravity fructose solvolysis to n-butyl levulinate: kinetic and calorimetry investigation.

Oral presentation for the 27th International Conference on Chemical Reaction Engineering ISCRE25, 11th-14th June 2023, Quebec Canada.

6.Daniele Di Menno Di Bucchianico, Giordano Emrys Scarponi, Jean-Christophe Buvat, Sébastien Leveneur, Valeria Casson Moreno, “Evaluating the economic feasibility of lignocellulosic biomass valorization through green-hydrogen: a case study in Normandy”

Poster presentation EUBCE31, European Biomass Conference & Exhibition, Bologna, Italy, 5-8 june 2023

7.Lujie Shi, José Delgado, Younes Aoues, Sébastien Leveneur, Thermal risk assessment with mixed uncertainty propagation in gamma-valerolactone production

Oral presentation for 7 ICSRS 2023, November 22-24, Bologna, Italy

8.José Delgado, Wenel Naudy Vasquez Salcedo, Christoph Held, Henrik Grénman, Adiabatic hydrogenation of alkyl levulinates to gamma valerolactone.

Oral presentation for the 3rd Journal of Thermal Analysis and Calorimetry Conference and 9th V4 (Joint Czech-Hungarian-Polish-Slovakian) Thermoanalytical Conference, 20–23 June 2023, Hungary.

9. Daniel Edumujeze; Marie-Christine Fournier-Salaun; Sebastien Leveneur, Green solvent and catalyst synergy: maximizing furfural yield from xylose dehydration.

Oral communication for The International Symposium on Green Chemistry (ISGC2025), May 12TH - 16TH, 2025, La Rochelle, France.

2020-2022: PHC Balaton ”Numerical methods for the optimization and safe production of non-isocyanate polymers”

Collaboration between INSA Rouen Normandie (France) & with the Institute of Chemical and Process Engineering, University of Pannonia (Hungary).

Principal investigators: Sébastien Leveneur (INSA Rouen Normandie) & Attila Egedy (University of Pannonia).

Total budget: 10k€

Scientific presentation

Fossil raw materials are the most used feedstock in the energy sector and in the chemical industry. For instance, 90% of organic chemicals are synthesized from petroleum or natural gas. Public authorities, industries and academies put a considerable effort into developing green and sustainable processes.

The use of vegetable oils, as renewable feedstock, for the production of chemicals or biofuels is a good illustration of this effort. The worldwide production of vegetable oil is increasing since 1975. The part of production for industrial use also increases and not only for biodiesel. Vegetable oils can be considered as platform molecules.